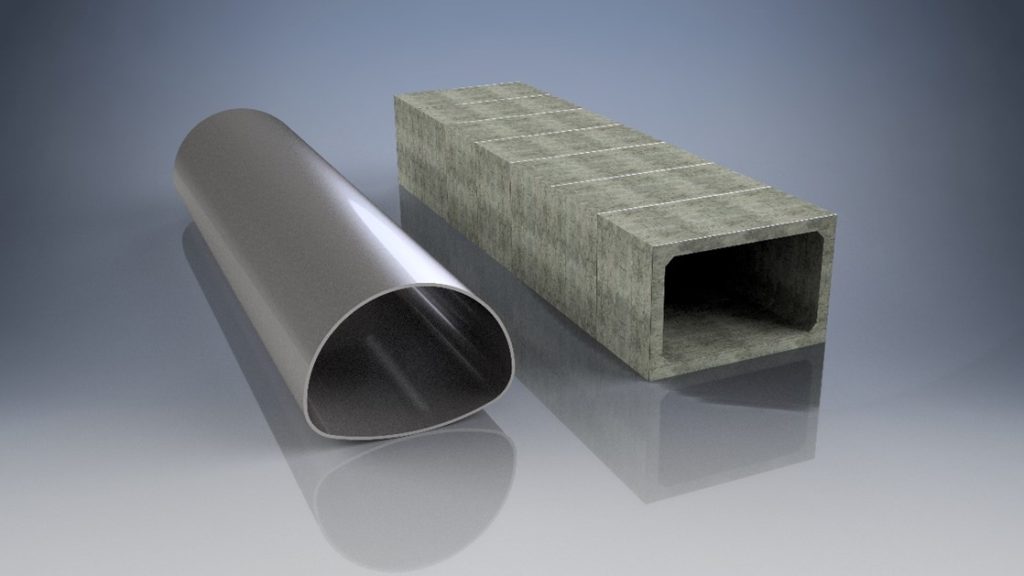

FARGO, ND — Precast reinforced concrete box culverts (RCBs) have long been a standard solution where depth or height restrictions demand wide, shallow conduits to handle adequate stormwater flow in county or city culverts and drains. However, precast box availability is very limited in the current market, and projects are continually getting delayed or pushed out. This scenario has also driven up the price for these products substantially.

Local townships, counties, DOT’s, and consulting engineers have been in contact with representatives in the Corrugated Steel Pipe (CSP) industry for precast box culvert alternative solutions; they are pleased to learn of the advantages CSP offers in place of box culverts and of the readily available steel supply.

Some advantages of CSP compared to RCBs:

- Economical and readily available

- Significantly less handling weight (ease of installation)

- Individual pipe lengths up to 60’

- Aluminized T2 and Polymer Coating

- Reduced carbon footprint

- Spiral Rib Corrugation profile offers 0.012 Manning’s “n” for replicable hydraulics

- Positive joints are great for resisting differential settlement and frost heave

- Custom fabrication and end treatments (step bevels / headwalls)

TrueNorth Steel CSP Sales Engineer, Brandon Scherber, elaborates on the advantages of CSP over RCB as concrete pipe alternatives, saying, “Reinforced precast concrete box culverts are one of many products that convey hydraulic flow in a specific drainage application. Given lead time and the current economic climate, we have found that many specifiers are open to alternates. These precast box culvert alternative solutions could be as simple as utilizing a multiple-barrel CSP installation or even a modular steel bridge. It’s just a matter of determining the cross-sectional profile, discussing site parameters and requirements, and looking into the design service life. Many drainage crossings can be widened slightly to allow for a CSP pipe option, and these pipe options allow for various end treatments that can be incorporated into the CSP design; headwalls, wing walls, beveled ends, or typical end sections.”

The following example compares a 108” Arched CSP (128” Span x 83” Rise) to a 10’ x 6’ RCB:

| Polymer Coated Arched Pipe 108” CSPA | vs | Precast Box Culvert 10’x6’ |

| Waterway Area = 60.5 FT2 | Waterway Area = 58 FT2 | |

| Minimum height of cover: 24 in. |

Minimum height of cover: 12 in.* (Minimum Cover Can Vary) |

|

| Joints per 42 LF = 0-1 | Joints per 42 LF = 6 | |

| Weight per ft = 183 lbs | Weight per ft = 4,625 lbs | |

| # of Installation Picks = 1 | # of Installation Picks = 7 |

Wilsey Road Drainage Culvert Project

A recently completed project example is the Wilsey Road Drainage Culvert project, completed by TrueNorth Steel in September of 2022. TrueNorth Steel worked closely with the county to re-design the Wisley Road project, which was originally slated to use reinforced concrete pipe (RCP). However, when county officials learned that CSP had a smooth interior option (Spiral Rib Corrugation Profile — Manning’s “n” value of 0.012) and that this pipe option would meet the design service life requirements with polymer coated steel, they were happy to make the product switch. The job was ultimately completed under budget and ahead of schedule.

Click to view images of Steel Alternatives to Box Culverts

TrueNorth Steel has over 75 years of experience in steel product solutions. If you have any questions, please reach out to TrueNorth Steel at drainage@truenorthsteel.com.