The National Corrugated Steel Pipe Association (NCSPA) recently awarded TrueNorth Steel with this year’s Project of the Year award in the Galvanized Coating category for the 90” CSP Vertical Monopole Casing project. The NCSPA is a prominent organization in the steel industry for its promotion of public policy and education regarding corrugated steel drainage systems in both public and private construction. The Project of the Year awards are made up of 13 categories ranging from DOT to Conversions, to Special Applications and identify steel industry projects that are recognition-worthy that were completed within the span of the last year.

Award Details

Category: Galvanized Coating

Project Location: Mountain Iron, MN

Size and Profile: 5×1, 90” round, 10 ga, galvanized CSP

Contractor: Lakehead Constructors

About

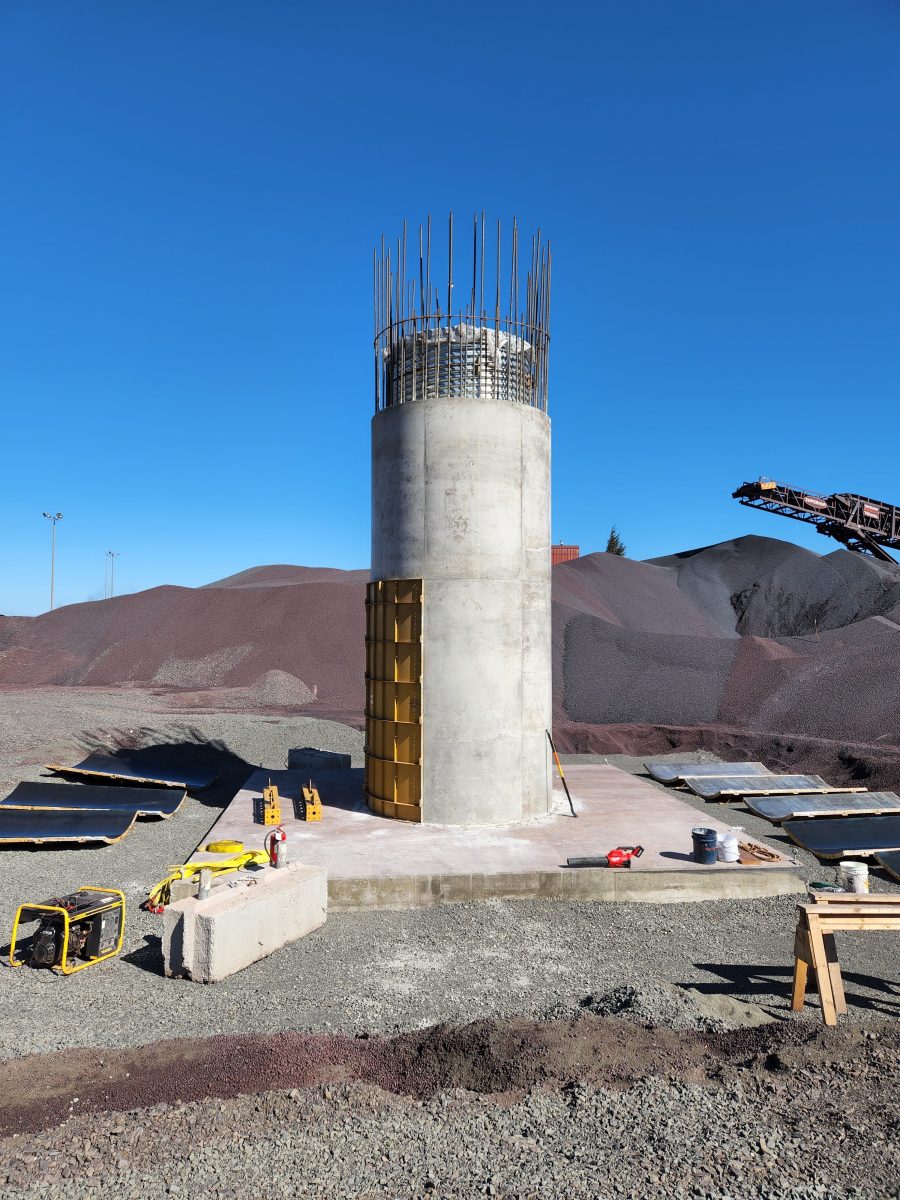

TrueNorth Steel was contacted about an application in which three vertical monopoles, approximately 50 feet in length, were being constructed in northern Minnesota to support a large conveyor system that would soon be transporting pellets for taconite processing. TrueNorth Steel conducted pre-construction meetings to discuss the pad and pier foundation, concrete pouring process, and the structural rebar reinforcing cages that were being used on the outside of the vertical pipes.

TrueNorth Steel’s Award-Winning Solution

Ultimately, TrueNorth Steel determined that a 5″ x 1″ corrugation 90″ diameter corrugated steel pipe (CSP) would function well for this undertaking.

A unique aspect of this project was that each of the three monopoles utilized two segments of CSP which had to be manufactured with strict length, outside diameter, and height tolerances to fit inside the custom rebar cage.

Though the pipes could have been fabricated in one piece, site conditions dictated that each monopole consist of two pipes and a band. Despite a short turnaround schedule, TrueNorth Steel was able to meet the contractor’s aggressive installation timeline and support the customer with multiple site visits.

As an added service, TrueNorth Steel also prepared as-built drawings that clearly outlined the specific labeling strategy (critical to ensure all the pipes were properly orientated) along with the fabricated dimensions of each component. This level of detail was critical to the success of the project since the pipes had to be inserted into two larger-diameter rebar cage cylinders. Each pipe had custom weld-on lifting lugs designed for a crane pick and placed so that the lugs did not interfere with the other components of the pier support assembly during the installation process.

TrueNorth Steel’s customized approach and attention to detail achieved the customer’s goals and kept the project on schedule.